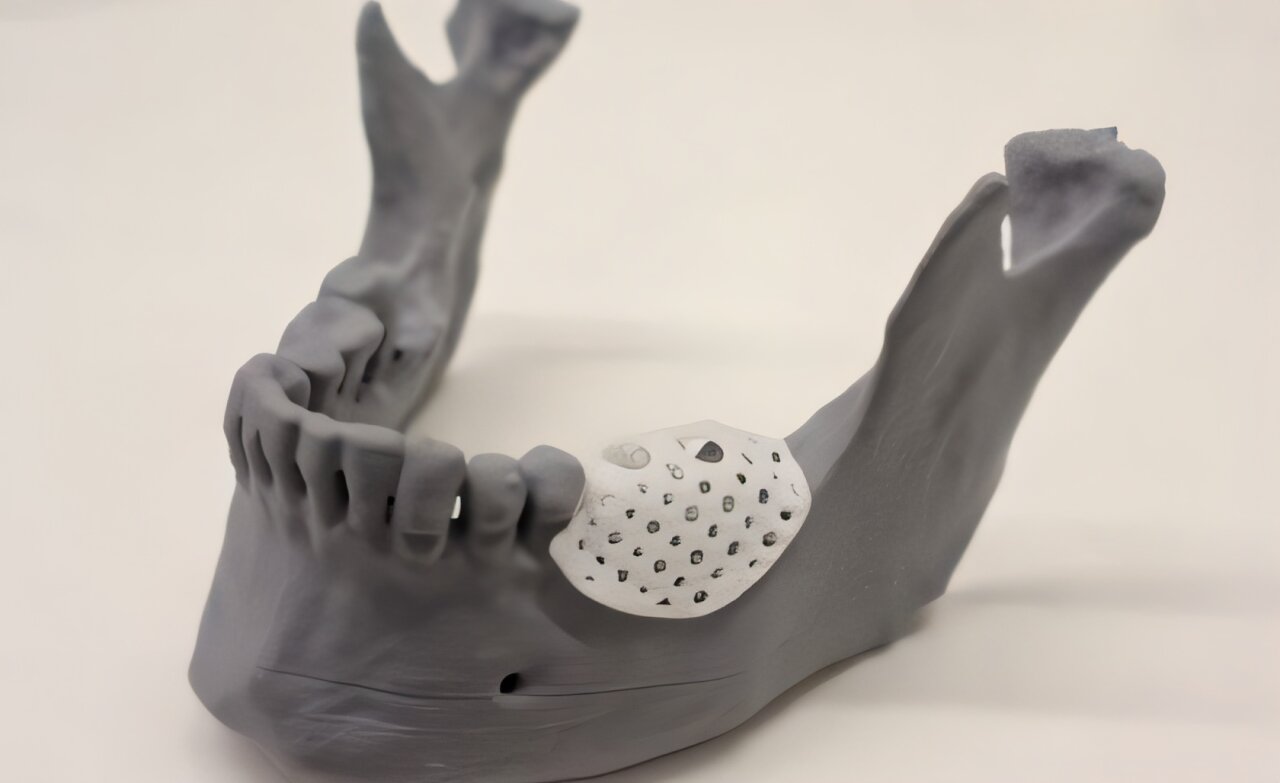

Clinicians have successfully used custom-made 3D printed bone scaffolds, printed on-site at The University of Queensland, to rebuild part of a man’s jawbone.

Professor Saso Ivanovski from UQ’s School of Dentistry, who led the clinical trial, said the case demonstrated the safe and effective use of the technology which uses biocompatible material—eliminating the need for secondary surgery to remove the scaffold. The research is published in Clinical Oral Implants Research.

“In this case, the scaffold supported and encouraged new bone to grow in the jaw of a 46 year-old man, allowing a dental implant with a new tooth to be securely inserted,” Professor Ivanovski said.

“The bone scaffolds are custom designed for the patient, effectively regenerate jaw bone and are completely resorbable, so there is no need for additional surgery to remove them.”

Since this initial success, more polycaprolactone (PCL) scaffolds have been printed at UQ’s Oral Health Centre and used in dental reconstructive surgery on a further nine patients.

Lead biomedical engineer Dr. Reuben Staples said the research highlights the huge potential of 3D-printing in personalized dental reconstruction.

“Our team is the first in Australia to locally manufacture university-developed 3D printed bone scaffold implants for dental reconstruction in human trials using our certified Quality Management System,” Dr. Staples said.

“It is compliant with the Australian regulatory requirements. Because the medical grade synthetic polymer used is more cost effective than currently available non-resorbable metallic commercial alternatives, this is a significant step forward in how 3D printing can be used to create affordable, safe and effective bone implant solutions to reconstruct jawbones and teeth for people in need.

“There is still more to be done in this field, but it’s exciting to see this success.”

The UQ team will now expand the trial to work with clinicians from around Australia and Spain to optimize the scaffold design so that it can be widely available for patients.

More information:

Sašo Ivanovski et al, Alveolar bone regeneration using a 3D‐printed patient‐specific resorbable scaffold for dental implant placement: A case report, Clinical Oral Implants Research (2024). DOI: 10.1111/clr.14340

Citation:

3D printed scaffolding to rebuild jaw bones: Clinicians have success using custom design (2025, January 9)

retrieved 9 January 2025

from https://medicalxpress.com/news/2025-01-3d-scaffolding-rebuild-jaw-bones.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.